Brandt 5200EX GrainVacs

Selling Price

Contact for price CAD

+HST & Licencing

Overview

Specifications

|

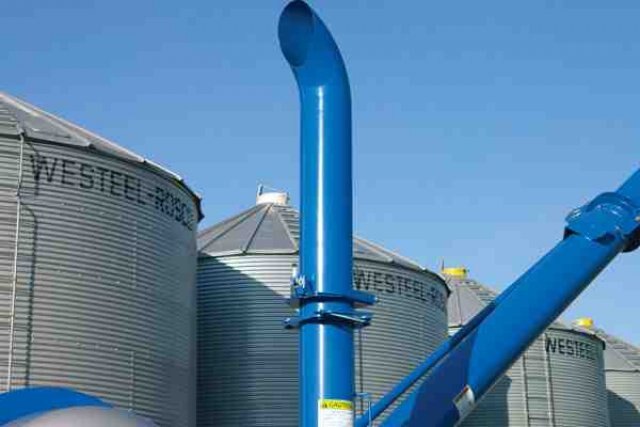

With the GrainVac 5200EX, turn one of farming's toughest jobs into a quick and

Brandt's GrainVac technology provides high capacity & high efficiency with lower horsepower requirements. A low-cost, easy to maintain solution for cleaning out the bin. The GrainVac 5200EX is capable of moving up to 5,000 bushels per hour in wheat or up to 5,800 bushels per hour in canola with a straight hose. The GrainVac has a low 70 horsepower requirement, which allows operators to use smaller tractors - cutting fuel costs, and lowering the cost of grain handling. |

|

Features |

|

Low Profile Design

Low Horsepower Requirement

Easy to use and Maintain

Fully Adjustable Bin Snake

Air Diffuser

Belt Drive System

Full Flow Steel Exhaust

Clean Up Shovel

GrainVac Pile Driver

|

Model

5200EX GrainVacs

Category Name

Agriculture

Year

2014

Sale Type

New

Manufacturer

Brandt

Quantity

0

Manufacturer Qty

0

Capacity

4500 - 5500 bu/hr

Auger Diameter

10 in

Width

102 in

Transport Height

85.5 in

Book a Demo

Contact Sales

What’s my trade-in worth?

Can I get financing?

Year

2014

Make

Brandt

Model

5200EX GrainVacs

Trim

N/A

Transmission

N/A

Type

N/A

Fuel Type

N/A

Exterior Color

N/A

Interior Color

N/A

Drive Type

N/A

Engine

N/A

Vin

N/A

Body Style

N/A

easy task. The GrainVac 5200EX has extended reach and high capacity for emptying out fill bins and in clean-up roles.

easy task. The GrainVac 5200EX has extended reach and high capacity for emptying out fill bins and in clean-up roles.